My uncle Adolf is probably most directly responsible for my interest in electronics. When I was growing up, he and Aunt Wanda ran A&W Electronics, retailing and repairing TVs and other equipment. This was back in the days of chassis construction, before circuit boards, when everything was built onto a metal chassis with insulating standoffs, vacuum tubes, lots of wire, and lots of solder.

When they received TVs that were irreparable, he’d often remove the dangerous parts (picture tube, flyback transformer, and huge capacitors) and give the remaining pieces to my brother and me to take apart. Which we did with great zeal, and a couple of wirecutters. I still have boxes of components that we salvaged out of those TVs; and man, they don’t make resistors and capacitors like they used to. And that’s mostly a good thing.

So when they had a household auction recently, in preparation for moving to a retirement community, I was pleased and proud to purchase two boxes of soldering equipment.

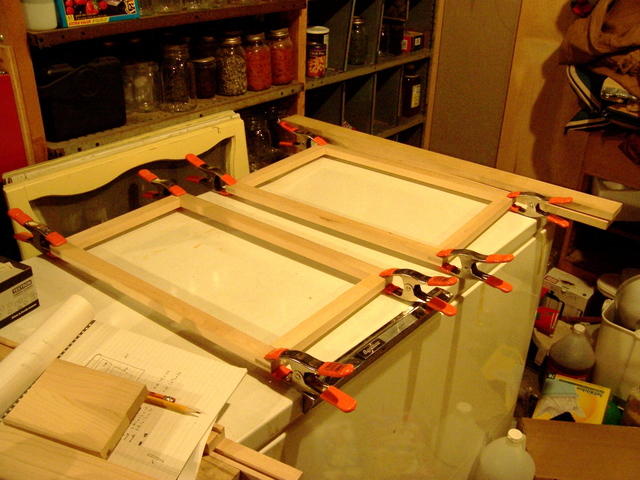

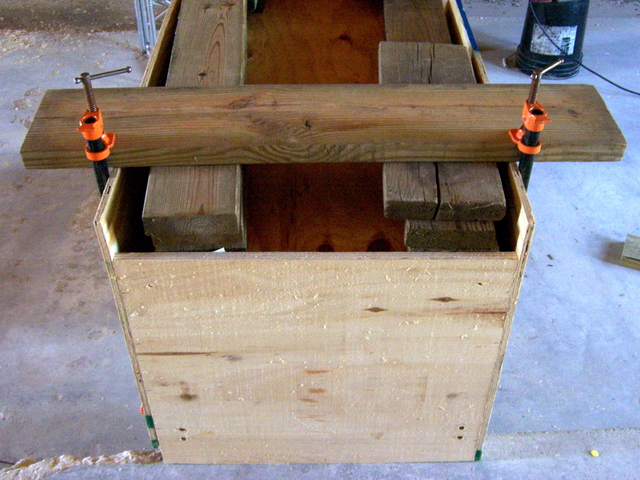

I could see the Weller/Ungar pencil irons, and knew that any one of them was worth the $16 I paid for the box. It wasn’t until I got home that I could really see what all I got:

There’s just an amazing amount of stuff crammed into the boxes. These irons have replaceable, screw-in heating elements, and the boxes have several spares of different wattages. One or two of the elements have replaceable tips like we’re used to using these days, and there are plenty of spare tips, too. Eventually, I plan to go through everything, sort out what goes with what, and do a little cleaning on the pieces that do fit together–replace brittle power cords, clean iron handles, polish heating elements, etc.

So?

I desolder a lot of components from dead electronic equipment that people give me. I really prefer older stuff with through-hole components, because SMT parts are a pain to identify and sort, and through-hole stuff is easy to prototype and breadboard with. The fastest method I’ve come up with is to pry up crimped leads with a $2 chisel, heat the solder side with a heat gun, and pull the components out with a chip puller or needlenose and drop them into a tub.

Generally.

Except (he finally gets to the point) for the TO-220 MOSFETs on the printer boards. For whatever reason, their through-holes were plated only barely larger than their leads, and I was having a dickens of a time desoldering them with the heat gun. The board was scorching, I was breathing really noxious fumes (and I like the smell of solder flux, but not so much burning fiberglass epoxy), I was bubbling and flexing the board as I pulled on the FETs’ tabs with a pliers, and still no joy. I ended up pulling the entire plated through-holes clean out of the board (um, maybe “clean” isn’t the best word to use here) and sliding them off the transistors afterward with my soldering iron.

And the Iron?

I’ve previously desoldered with soldering irons and guns, and under some circumstances, direct heat can be very effective at removing stubborn leads. So a couple of nights ago, I got around to digging through the auction boxes to see whether I could find a wide tip. I was looking for something that would hit all three transistor leads at once, and I found exactly that–a gimongous .3″ chisel-tip 40W heating element, still sealed in its original bubble package.

I opened the package, cleaned the oxidation off the tip, screwed it into one of the handles, and plugged it in. When it started getting up to temperature, I smiled in appreciation at the ceremonial first tinning of the new tip. I grinned at its extreme shininess as I wiped off the solder on the damp sponge. I dropped my jaw in amazement as the transistor slipped right out of the board in about a second of applying the tip to the leads. I desoldered the remaining thirty or so transistors in a matter of brief minutes.

The tip kept heating up the whole time. As I was finishing, I would occasionally cast shadows on the iron and see that the tip was now red-hot. I’d wipe it on the damp sponge and see little embers rise into the air as it tore off and burned rough parts of the sponge surface. I was rather unnerved to see this from an element rated at 40W.

But boy, did it desolder them transistors! Yee-haw!

Obligatory FPS Reference

I’m somehow reminded of the differing effectiveness of various weapons against various monsters in Doom. When you run into a cacodemon, you better make sure you have the nailgun handy–even though it’s utterly useless against several other species.